Digital Flatbed Cutting Plotter FC-500VC

Perforation Cut | Full Cut | Kiss Cut | Creasing

The VICUT Vulcan Series Flatbed Cutting Plotter is the ideal solution for small to medium production environments producing packaging prototypes, swing tags, cards and label samples.

It processes a wide range of materials including:

Paper

Cardboard

Synthetic materials

Films

Self-adhesive labels

Media up to 600gsm

Advanced Digital Contour Cutting Technology

Using advanced digital contour cutting technology, the Vulcan Series enables you to produce custom shapes directly from your desktop — without the need for cutting dies.

This eliminates tooling costs, reduces turnaround time and allows for fast prototyping and short-run production.

The machine supports:

Full cut

Kiss cut (half cut)

Creasing

Perforation

Drawing

Perfect for packaging mock-ups, sample production and customised short runs.

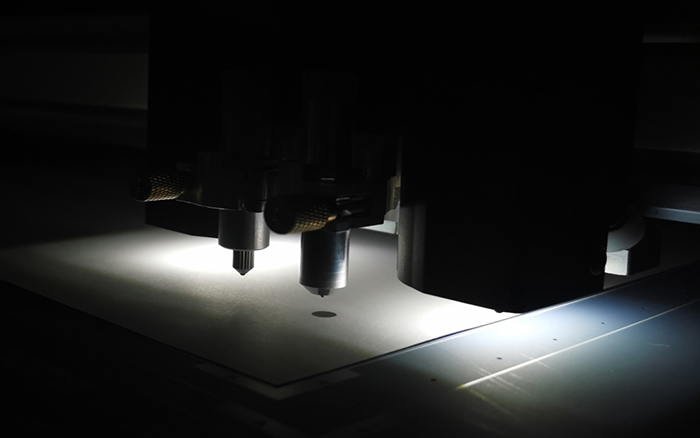

High-Resolution Camera System

The FC-500VC and FC-700VC feature a high-resolution camera for precise detection of registration marks as small as 5 mm.

Detects marks on both coloured and transparent materials

Scans four registration marks in under 3 seconds

Allows smaller reg marks, reducing material waste

Improves production speed and lowers overall costs

This advanced camera system ensures accurate contour cutting and reliable performance across a wide range of applications.

User-Friendly Touchscreen Interface

The intuitive touchscreen interface is designed for simple and efficient operation.

Key Features:

Vacuum suction control:

ON – Fast, stable material hold

OFF – Easy material changeover

Adjustable carriage speed:

Fast (×10)

Slow (×1)

One-touch origin setting or return-to-origin for accurate positioning

Dedicated Re-Cut button to instantly repeat the last job

This streamlined control system reduces setup time and improves workflow efficiency.

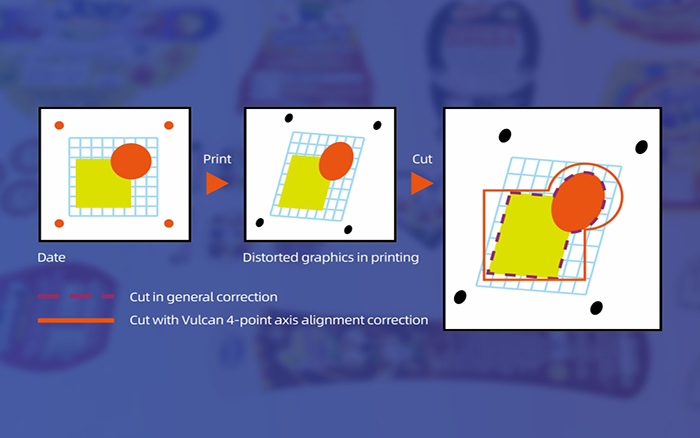

Advanced Contour Cutting

The Vulcan flatbed cutting plotter is engineered for high-precision contour cutting, even when materials are loaded slightly off-angle.

Automatically compensates for slanted placement

Corrects size and shape distortions

Utilises a proprietary four-mark detection algorithm for maximum accuracy

This ensures clean, consistent results across every sheet.

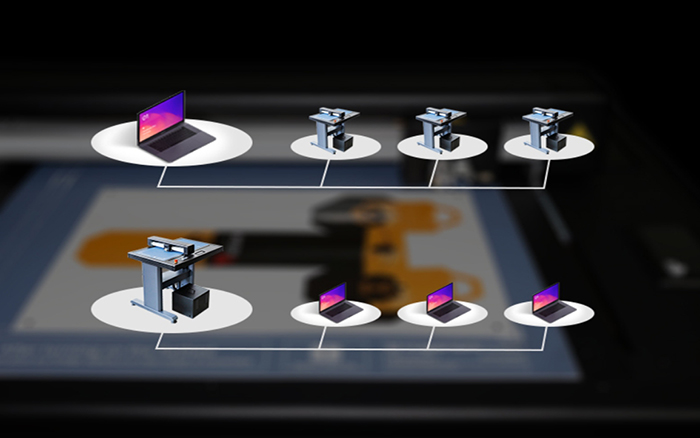

Network Interface

Built-in network connectivity provides flexible production control:

Stable long-distance communication

Control one flatbed cutter from multiple computers

Control multiple flatbed cutters from a single computer

Ideal for busy production environments and shared workspaces.

U-Disk (USB) Function

PLT files saved to a USB thumb drive can be sent directly to the cutter.

Operate without a computer connection

Perfect for repeat jobs and standalone production

Simple and efficient workflow

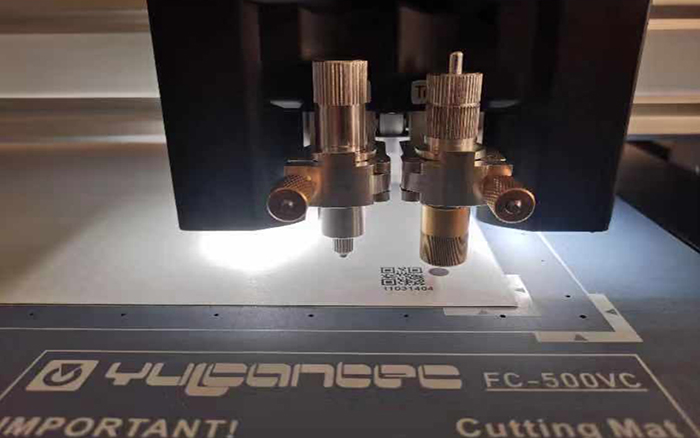

QR-Code Workflow System

The flatbed cutter reads QR codes printed on media to automatically match print and cut files.

Eliminates file mismatches

Speeds up job setup

Ideal for multi-job production runs

This intelligent system improves reliability and reduces operator error.

SignCut Pro Software

Compatible with SignCut Pro offering:

Powerful standalone cutting software

Ongoing updates

Lifetime technical support

Designed to deliver professional performance with continuous software improvements.